What and how to lubricate?

3D printer has several moving parts. Main things are printheadtoolhead and bed. Toolhead moves in X and Y directions, bed moves in Z direction

Cleaning and greasing rods should be done every month on heavy usage or at least once per three months

Also read: Which lube to use?

X-Max 3 and X-Plus 3

X and Y axis

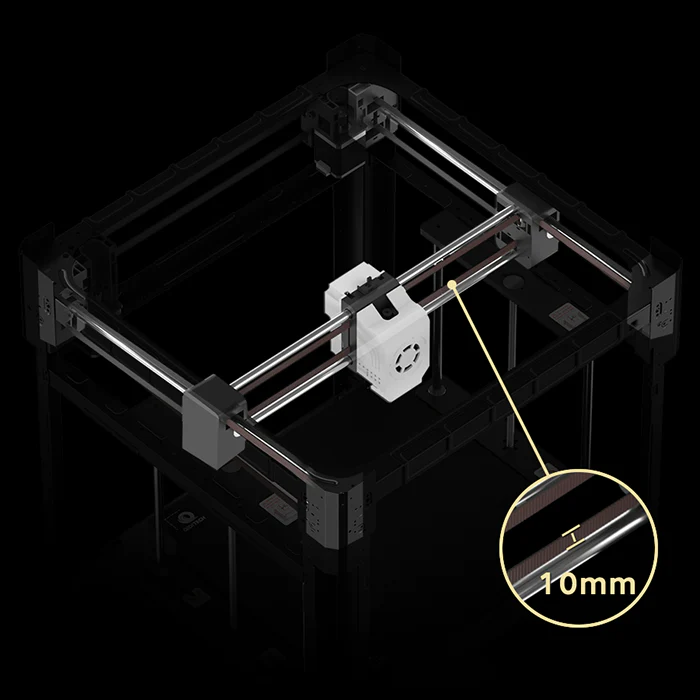

X-Y rods are steal beams, two going across the bed and one on each side

(Picture from Qidi marketing materials)

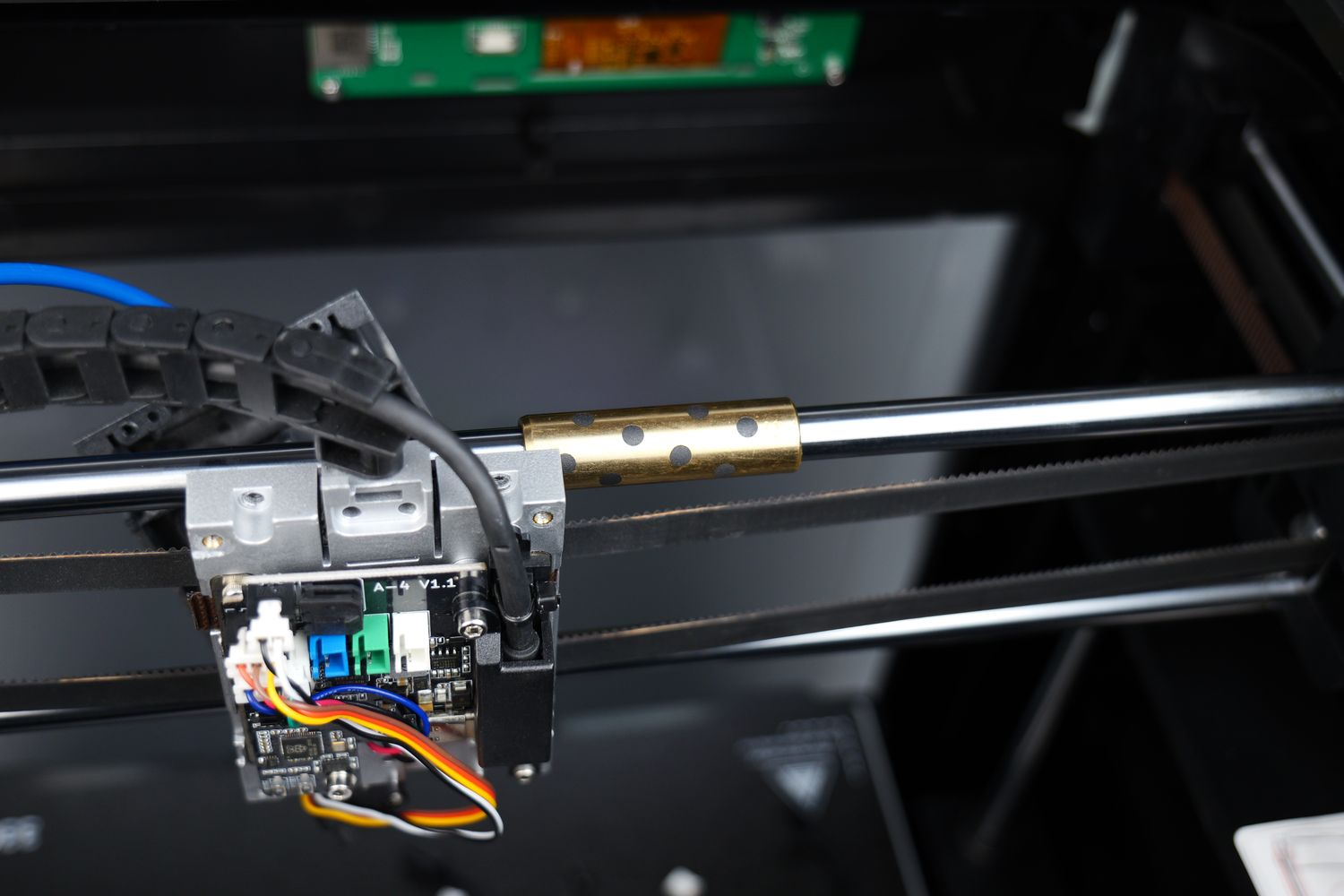

X-Max 3 and X-Plus 3 use two kinds of different bearings. On Y axis, on both sides of bed, they have LMU10UU bearings (regular ones basically). On X axis (across the bed) they have graphite impregnated bushings, which are self-lubricating. Applying any liquid lubricant to X axis bearings might make graphite glog up and make things worse (I sent mail to Qidi support to ask about it. Will update when I get response - McSneaky)

(Graphite impregnated bushings, picture by https://3dprintbeginner.com/qidi-x-max-3-review/)

To lubricate rods on the side of bed, move toolhead to one corner, clean rods with soft cloth - to remove all dust and particles. Move toolhead to another corner and re-wipe all

Apply grease on cloth or rods and spread it across them. Move toolhead to other corner and re-do the process

It's important to not apply too much lubricant, since it will have the opposite effect - it makes printer movements harder and will start to accumulate dust and particles

After lubeing move toolhead from corner-to-corner several times, to ensure grease is spread evenly across the rods and inner bearings

Z axis

Z axis has two leadscrews and four lineral rods with LMU10UU bearings. They require periodic maintainance (1-3months). Workflow is the same as Y axis: move bed down, clean the rods with soft cloth of old grease and dust. Move bed up, clean part that was inaccessible before. Apply grease sparingly to rods and leadscrews on both side of bed. Try to spread the grease while applying it with fingers, cloth or tip of the grease container. Don't overdo it, since too much grease will start to accomulate dust and particles

After applying grease move bed up and down several times, to make sure grease is spread out evenly

(Rods and leadscrew on one side. Picture by https://drucktipps3d.de/qidi-x-max-3-testbericht/ )

X-Smart 3

X and Y axis

X axis carbon rods don't require any lubrication. They just need to be cleaned from dust every some weeks. That can be done with soft cloth. If you really want to lube, make sure you use synthetic PTFE lube.

Petrolium and mineral based lubes will react with carbon-fiber bonding material and damage the rods!

Y axis works the same as all other X-3 series printers:

- Move toolhead to one corner

- Clean rods with soft cloth of dust, debry and old grease

- Move toolhead to other corner and re-clean with cloth

- Apply grease to rods on both side of bed, trying to apply it evenly on the rods

- Move toolhead back to first corner

- Apply grease to previously inaccessible parts

Try to apply grease evenly on the rod, by evening it out with finger, cloth or tip of the grease container

Don't apply too much grease, as it will have opposite effect - increasing friction, will accomulate dust and debry

Move toolhead from corner to corner several times, to even out grease on the rods and in the bearings

Z axis

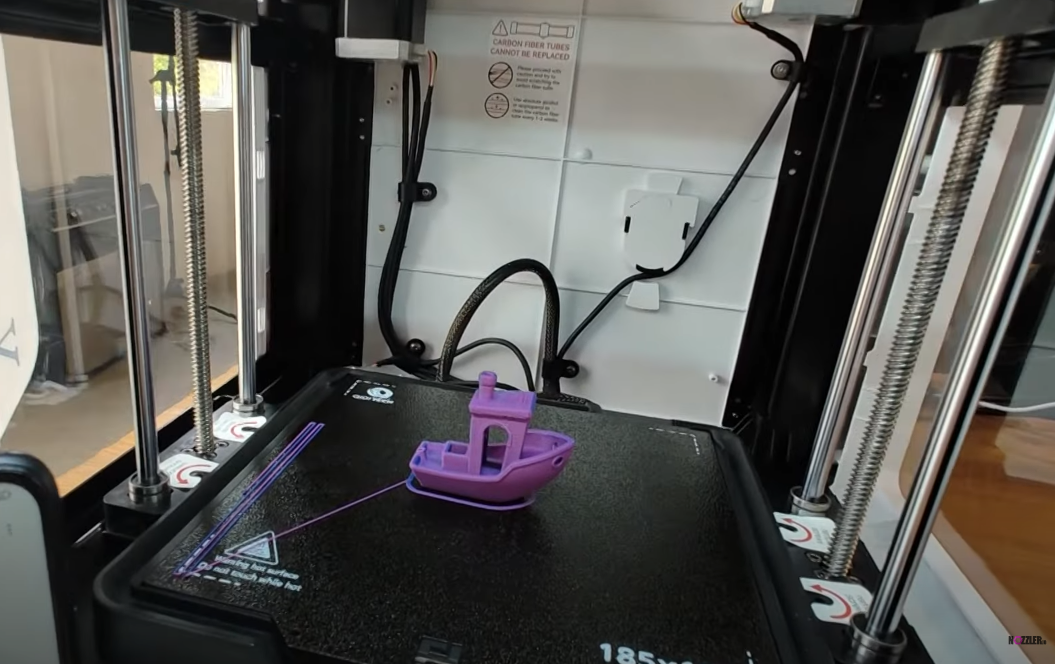

Works the same as other X-3 series printers. On both side of the bed there are two rods and leadscrew

(Picture from Nozzler Youtube video)

To lube them, same technique is used as for everything else. Move bed to one max, clean rods andleadscew with soft cloth from dust, debry and old grease. Move bed to other max and clean part that was inaccessible before. Apply thin layer of grease across the rods and leadscrews. Move bed to other max again to grease part that was blocked by bed

Don't apply too much grease, as it will have opposite effect - increasing friction, will accomulate dust and debry

Move bed several times up and down to ensure grease is applied evenly across the rods and bearings